On this page:

Thermal shocks

Thermal shock resistance test in a temperature chamber

Cold water thermal shocks – Water splash tests

Tests of resistance to thermal shocks in a shock chamber (cyclic action of air)

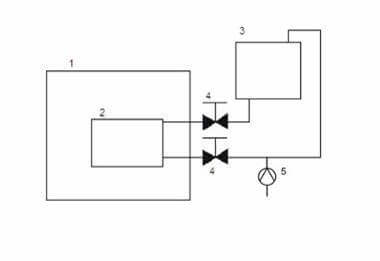

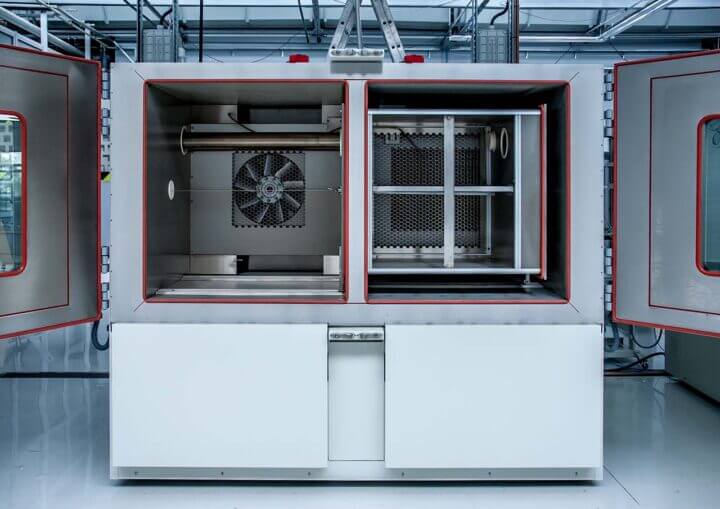

Climats shock chamber

he shock chamber is designed to expose test samples to thermal shocks. Accurate simulations in accordance with standards (including defense standards) are possible. The shock test in the device is carried out by means of an automatically controlled elevator moving between chambers at two extreme temperatures: high and low. The device is a horizontal chamber, i.e. the working chambers are located side by side.

The shock chamber makes it possible to test the resistance of parts and devices to rapid temperature changes (i.e. thermal shocks).

Testing (PCA accredited range) according to the following norms:

- PN-EN 60068-2-14

- PN-EN 60068-2-1

- PN-EN 60068-2-2

- VW 80000 (K-16)

- GS 95024-3-1 (K-05)

- Others (within the technical capabilities of the chamber)

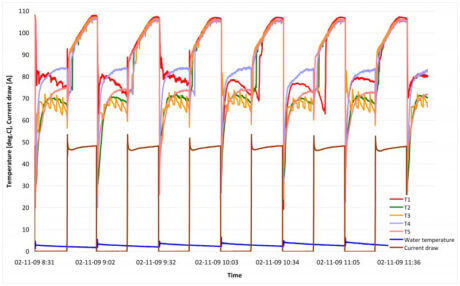

Cold water thermal shocks – Water splash tests

Testing resistance to thermal shocks caused by cold water – Water splash tests

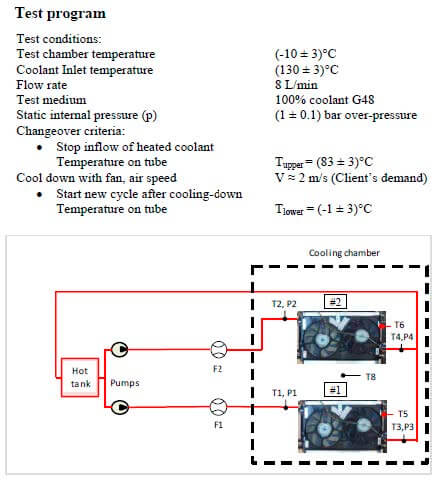

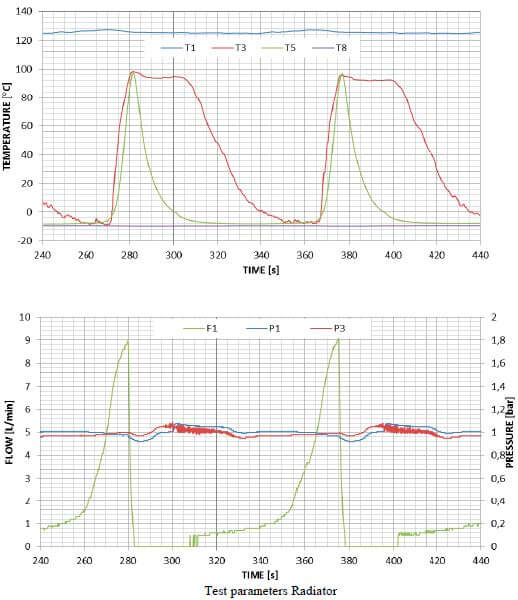

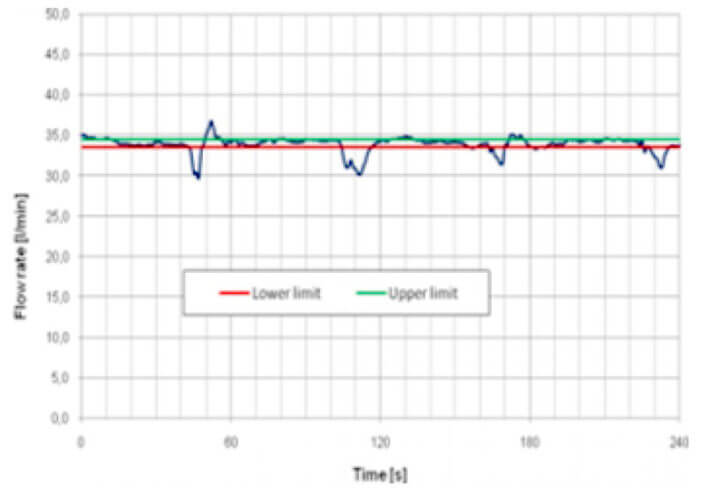

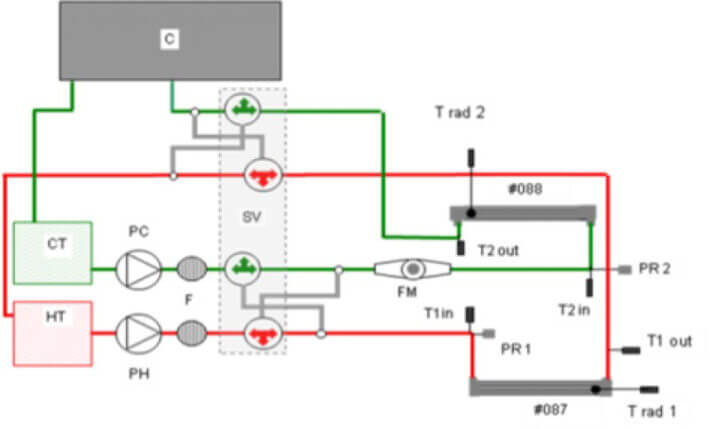

Test description:

The test aims to simulate the cyclic splashing of heated up elements with cold water.

Examples of test objects:

Engine cooling modules, lamps, solenoid valves, wiring/tubing bundles and others.

In addition, we provide glycol or oil circulation to the test objects, as well as electric cycles (if required).

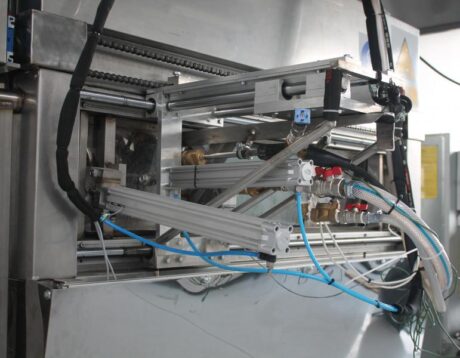

Splash test chamber – test bench technical parameters:

- chamber operating temperature range: 30 – 170°C,

- water temperature range: 0 – 20°C,

- dimensions of the workspace: W x H x D = 1500 x 1180 x 1250 mm,

- nozzle speed (with cold water): 1 – 25 cm/s,

- water flow: up to 60 l/min,

- possibility of using water-dust mixtures.

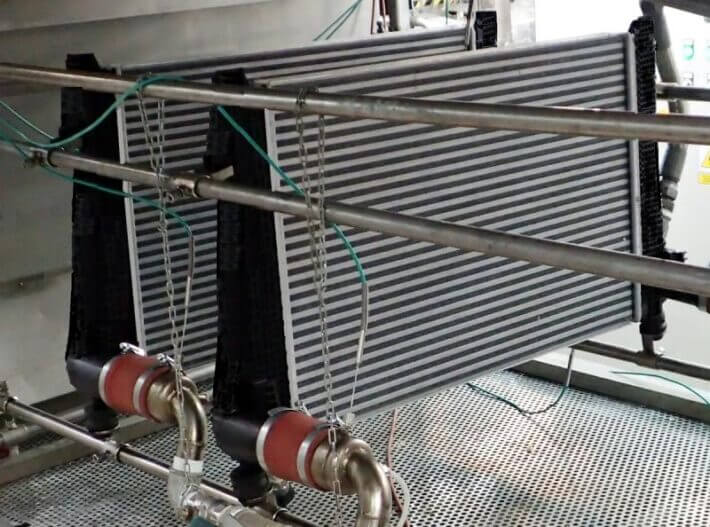

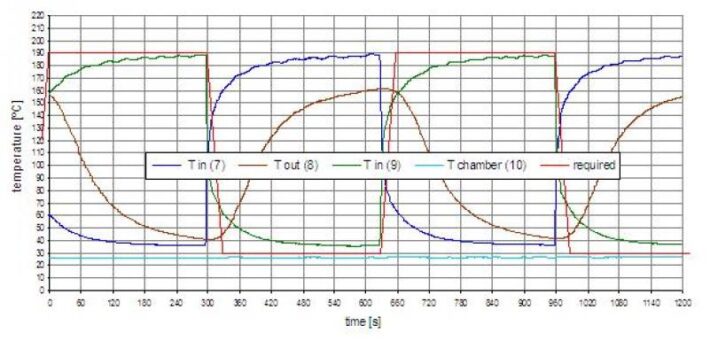

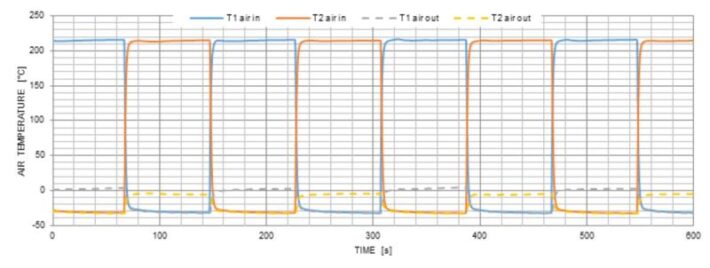

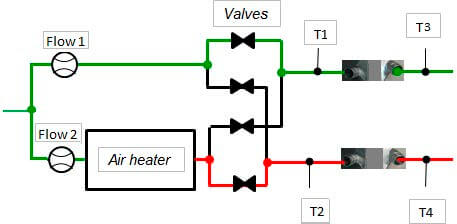

Thermal shocks – air

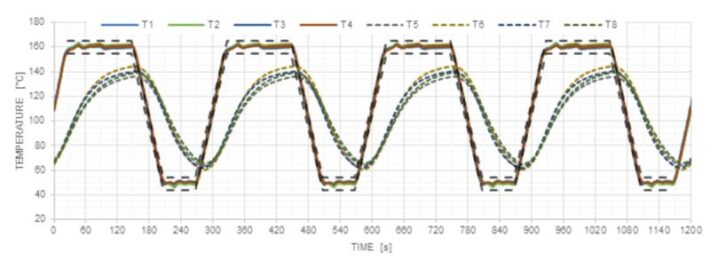

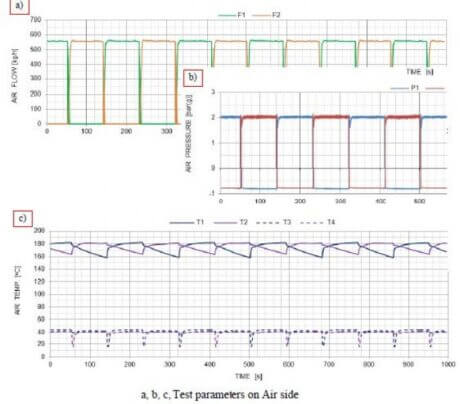

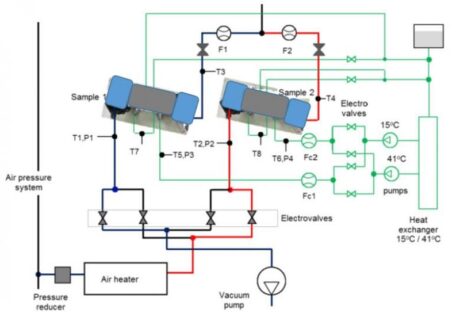

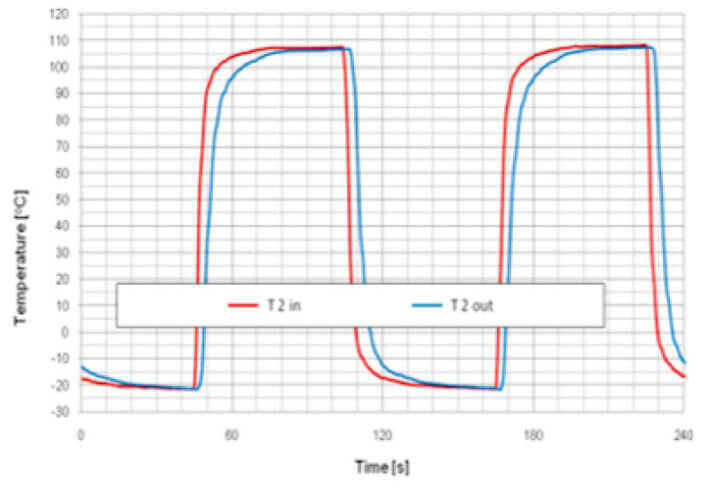

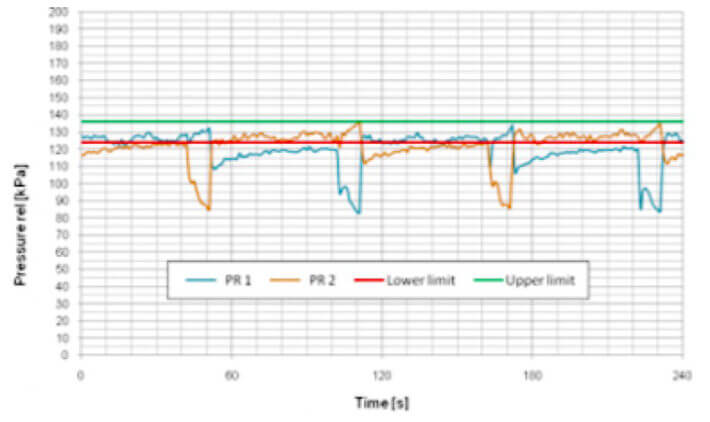

Thermal shocks (air) of intercoolers

Technical parameters (examples)

- Operating pressure: up to 5 bar

- Air temperature (hot phase): up to 250°C

- Air temperature (cold phase): down to -30°C

- Air flow: up to 0,4 kg/ s

- Cycle time: 2-20 min (or other times)

- Cooling air flow: up to 5m/s

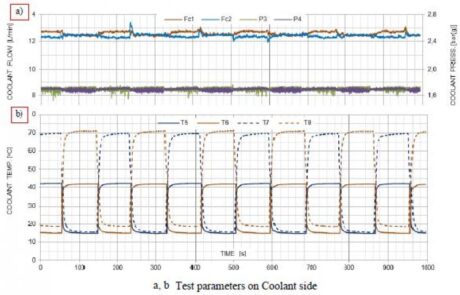

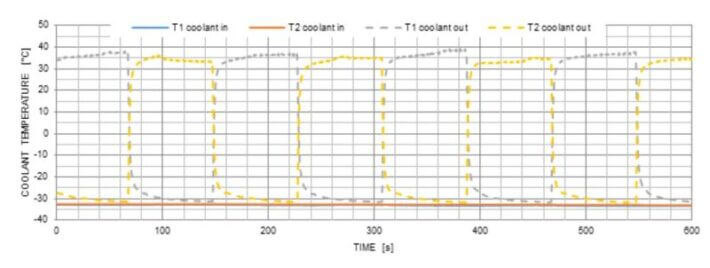

Thermal shocks (air) of WCCACs (Water cooled charge air coolers)

For WCCACs (water cooled charge air coolers) – additional temperature controlled water/coolant circuit available.

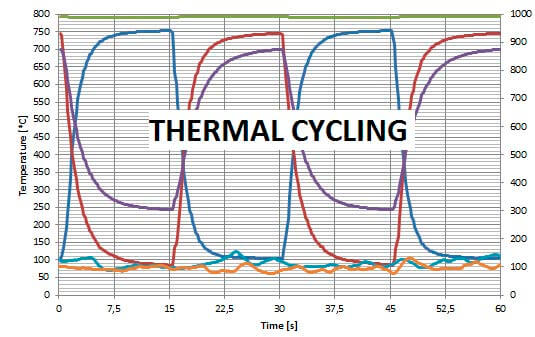

Thermal shocks of exhaust gas recirculation (EGR) systems & exhaust systems

Technical parameters (examples)

- Operating pressure: up to 5 bar

- Air flow: up to 100 kg/h

- Air temperature (hot phase): up to 750°C

- Air temperature (cold phase): up to 100°C

- Cycle time: 0,5-5 min (or other times)

Thermal shocks – glycol, water

Testing of thermal shocks (glycol, water) at ambient temperature

Powrót

do góry strony