On this page:

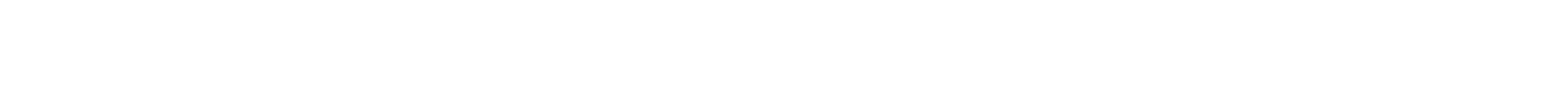

Testing vehicles’ electrical and electronic equipment

Testing wiring harnesses, connectors, push connections (crimps) and other components

The range of tests of wires and wiring harnesses

- measurement of the active resistance of conductors

- studies on the influence of environmental factors on wiring insulation (ageing tests)

- measurements of the electrical parameters of wiring insulation (electrical resistance and durability)

- tests of mechanical parameters (impact, stretching, winding)

- tests of resistance to chemical agents

- other tests, within our technical capabilities.

In the photo: continuity test of winding wire insulation

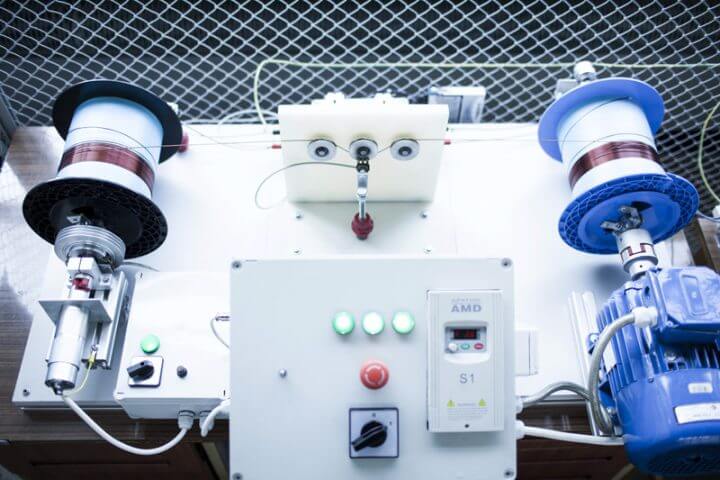

The range of tests of connectors and crimp connections

- measurement of voltage drops with determination of resistance: connections, crimp connections, connector material

- measurement of the temperature increase at a joint as a function of current load

- studies on the influence of environmental factors on joint parameters (e.g. high temperature, salt spray, vibrations, thermal shocks)

- cyclic tests

- tests of electrical durability and measurement of connectors’ insulation resistance

- tightness testing of hermetic joints and sealed cable connections

- other tests, within our technical capabilities.

In the photo: sample test objects – crimp connections with eyelet mounting terminations

Technical parameters of the tests

Tests for the voltage range up to 1000 V and current loads up to 240 A

Testing sensors and transducers

BOSMAL performs various types of electronic and electrotechnical tests of sensors and transducers. These include:

- measurements of electrical parameters and characteristics,

- testing of resistance to environmental conditions.

Measurements of electrical parameters and characteristics of sensors and transducers

BOSMAL performs measurements of electrical parameters and sensor characteristics:

- ABS,

- shaft position,

- oxygen content in the exhaust (lambda sensor),

- relative pressure of exhaust gases,

- LPG gas level,

- temperature (mirrors, air-conditioning system and others),

- distance ((for parking and collision avoidance),

- position of the angle of heel of the vehicle,

- others in terms of technical capabilities.

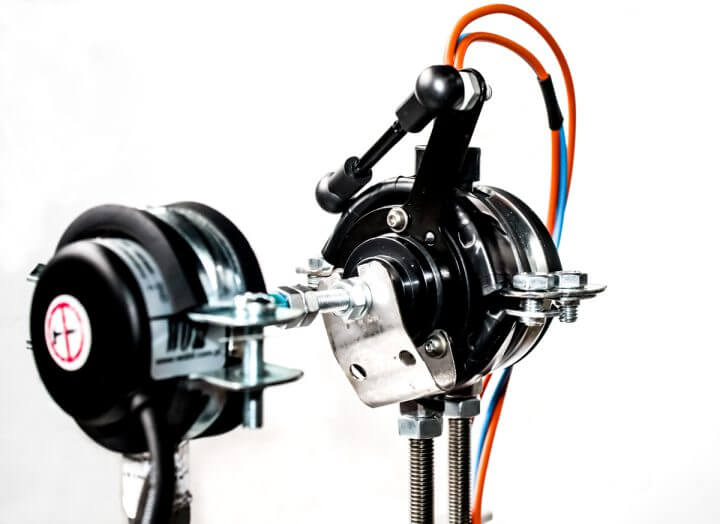

In the photo: tilt angle sensor

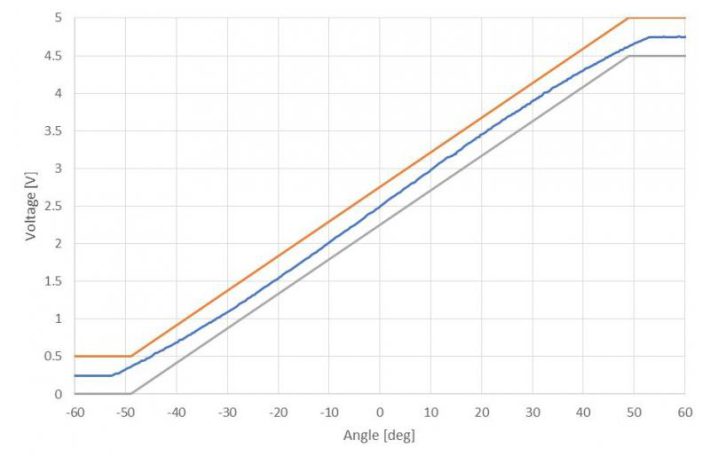

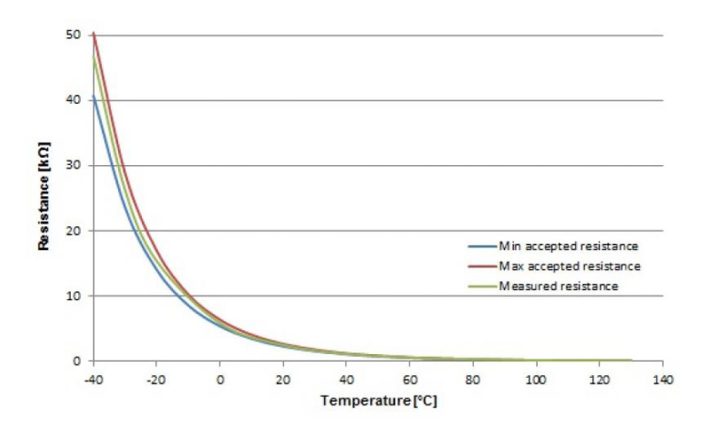

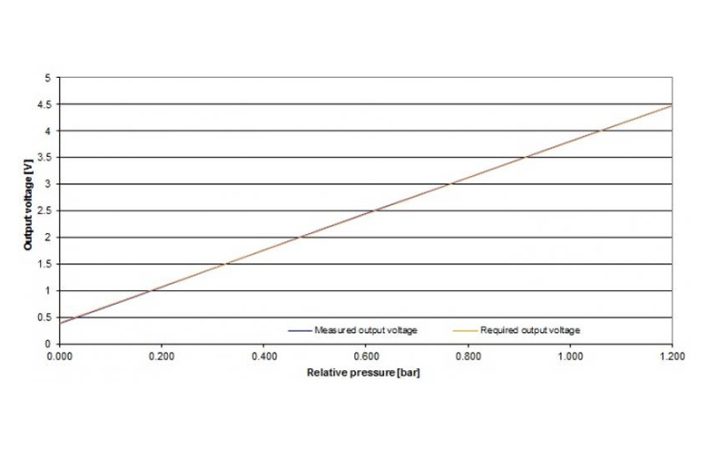

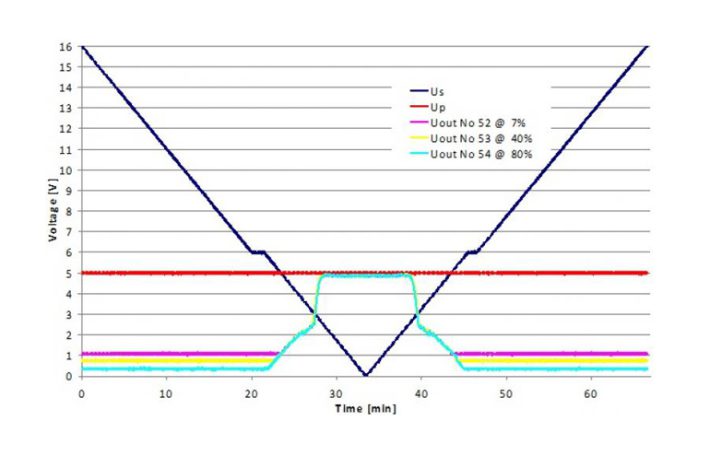

Sample characteristics:

Exterior and interior vehicle lighting systems

Systems of external and internal lighting of vehicles are subjected to tests such as:

- durability and functional tests (including vibration tests – including vibration tests of electronic systems embedded in lighting fixtures).

- tests of resistance to environmental conditions (e.g. tests of resistance to dust and water),

- optical tests,

- material tests.

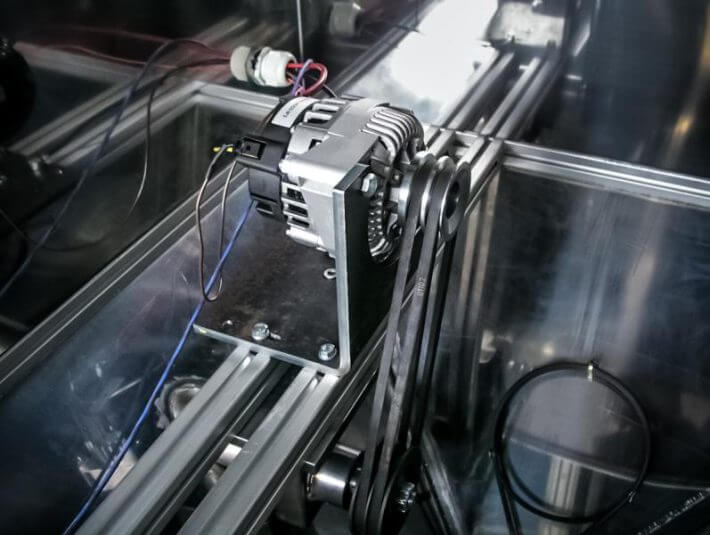

Alternator testing

Other electrical equipment

BOSMAL also performs tests of electrical equipment:

- seat heating systems,

- dampers,

- pedals,

- antennas,

- and other components and products.

Among other types, thermovisual measurements are carried out.

Powrót

do góry strony