On this page:

Technical cleanliness inspection – internal and external cleanliness of products

Product cleanliness testing – qualitative and quantitative methods

Product cleanliness testing is a very important element in the quality assessment of many components, especially those which come into contact with operating fluids. Such tests are carried out in a clean room of ISO 6 cleanliness class (according to ISO 14644).

The basic factors determining the purity of the test object are: mass of insoluble impurities, mass of soluble impurities, amount of insoluble impurities of a certain size and type of contamination. In the case of insoluble (solid) impurities, it is possible to divide them according to their nature: metallic, non-metallic and fibres, as well as by chemical composition. In order to determine these properties, an appropriate extraction liquid is selected (it must be compatible with the component material) and the method of pollutant extraction is selected: agitation, pressure washing, ultrasonic techniques, or washing on functional test benches reflecting the working parameters of the test object. The choice of the extraction method depends on the characteristics of the test object and on the specified properties, i.e. internal/external/overall purity.

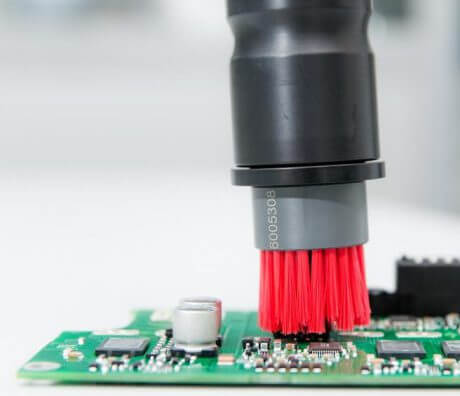

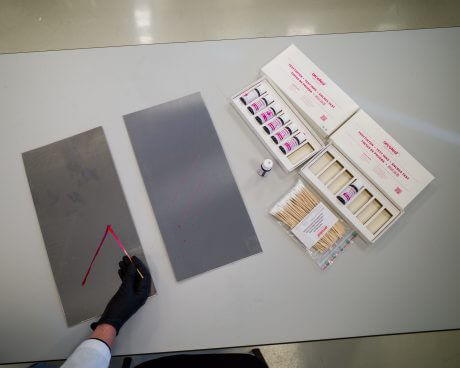

Particulate suction device

New testing technique – Particle extraction system:

- Non-destructive testing through dry air extraction

- Testing dedicated to large-size objects

- Inspection of the entire surface, including holes, etc.

- Testing dedicated to components that are not designed to come into contact with liquids or the use of liquids could remove significant contaminants from the workpiece / distort the result / damage the component

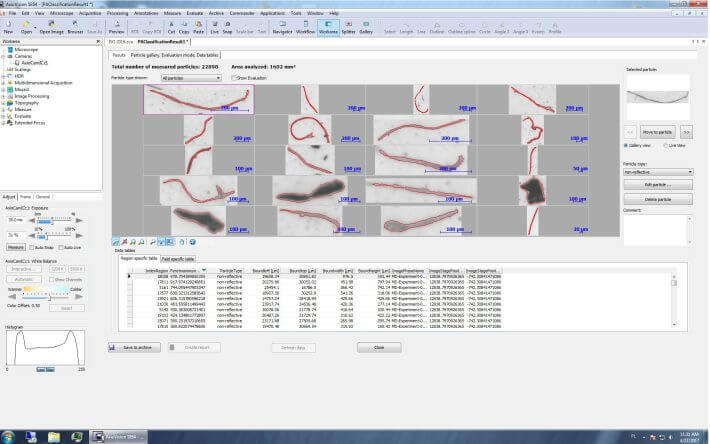

Extracted pollutants are analysed by the following methods:

- Gravimetric method (weight),

- Granulometric analysis (particle size, by length (Ferret max) or width (Ferret min)),

- Digital microscope,

- Scanning electron microscopy (SEM),

- X-ray fluorescence (XRF),

- Elemental analysis (chemical composition) – EDX, LIBS,

- Particle Type Identification – FTIR, Raman…,

- Filtration – cascade segregation on filters,

- Particle Counter.

Equipment

- Keyence VHX Series digital microscope with EA-300 Series laser elemental analysis head

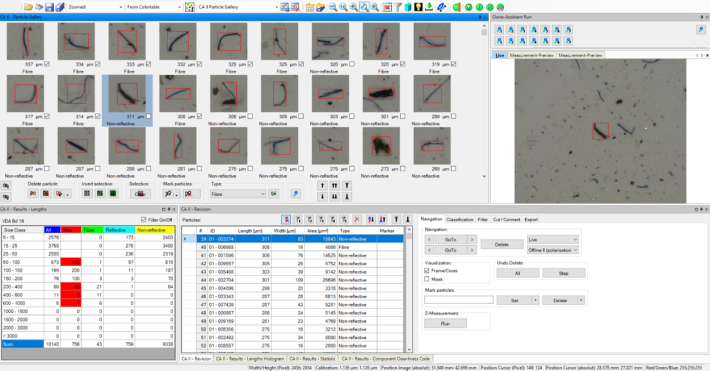

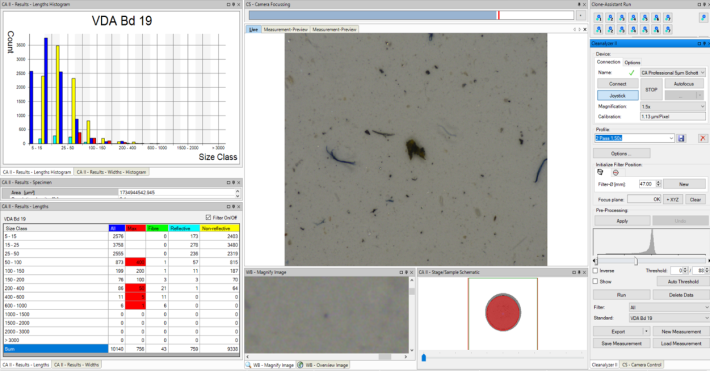

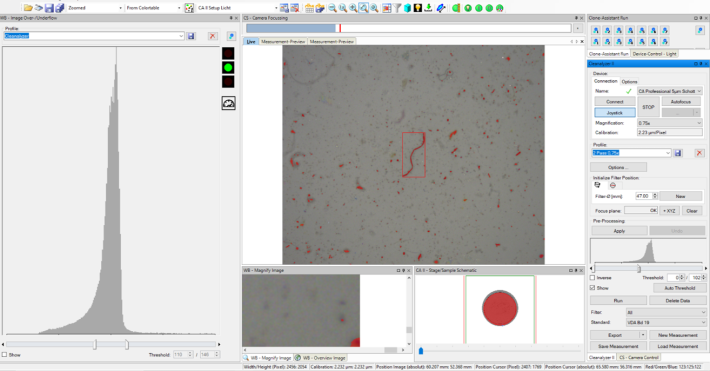

- dhs-Cleanalyzer Professional 5 µm optical microscope with motorized table. Particles are measured in size classes according to ISO 16232, VDA 19.1 and also other customer requirements.

- SEM EVO 25MA Zeiss scanning electron microscope with Bruker EDX and EBSD detectors

- FTIR Nicolet 6700 spectrometer

- Nicolet iS50 FTIR spectrometer with microscope

- PALL Cleanliness Cabinet PCC-41-R0220-NG2 automatic pressure washer (with the possibility of cleaning large-size components)

- Particulate suction device

- Ultrasonic cleaners

- Analytical balances

- Temperature chambers

Standards

BOSMAL is the only laboratory in Poland accredited for testing of cleanliness according to ISO 16232, VDA 19.1 and DIN 8964-1.

Testing norms

- ISO 16232

- DIN 8964-1

Testing norms from the industry and customers’ own norms

- VDA 19.1, QV 11111, DBL 6515, DBL 6516, PV 3347, PV 3370, PV 3336, VW 01134, VW 01137, Volvo STD 107-0002, Scania STD 4189, GMW 16037, NW 22-10-202, SAE J1726, Continental TST N 002 02.22, Wabco JED 593, BWS 42001, Renault 34-07-012, Renault 34-07-025, as well as others.

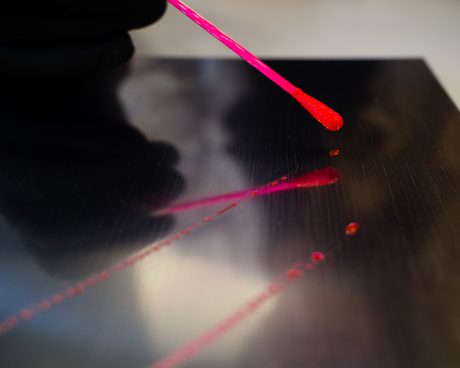

Evaluation of cleanliness by surface tension test

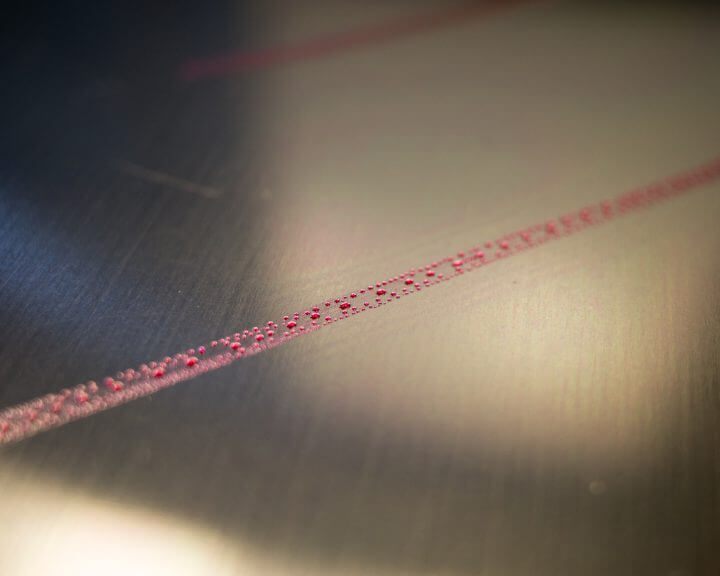

One of the quick and simple methods of determining the cleanliness of surfaces is to test the surface tension by applying test inks/markers.

Surface contamination – especially that resulting from metal alloys which are formed in the course of production process – reduces adhesion of paints, adhesives or galvanized coatings.

Clean surfaces have a material-specific surface tension. Clean surfaces have high surface energy, while in case of contaminated items, surface energy proves to be much lower.

It is assumed that the correct value of surface tension for metallic surfaces should be min. 44 mN/m for processes such as gluing, welding or coating to be effective. Typically, for cleaned surfaces, depending on the cleaning process applied, the surface tension ranges from 38 mN/m to more than 70 mN/m. In the case of oily surfaces, the surface tension ranges from 25 to 35 mN/m.

The cleanness assessment technique related to surface tension consists of applying a test ink with an appropriate value of the surface tension to the tested surface. Observing the behaviour of the stroke of ink on the surface allows determination of the minimum value of the surface tension of the test object.

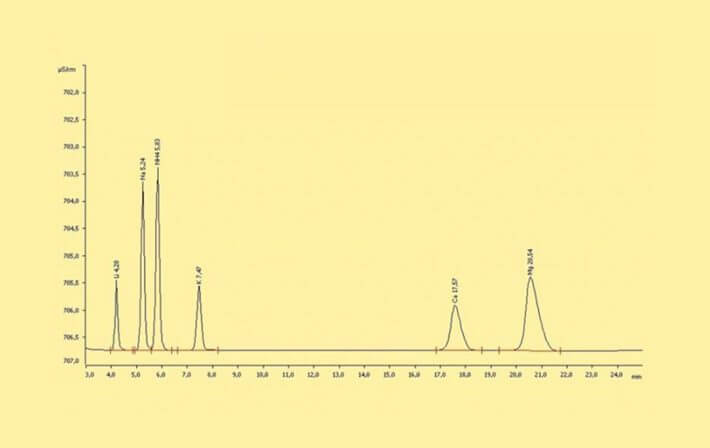

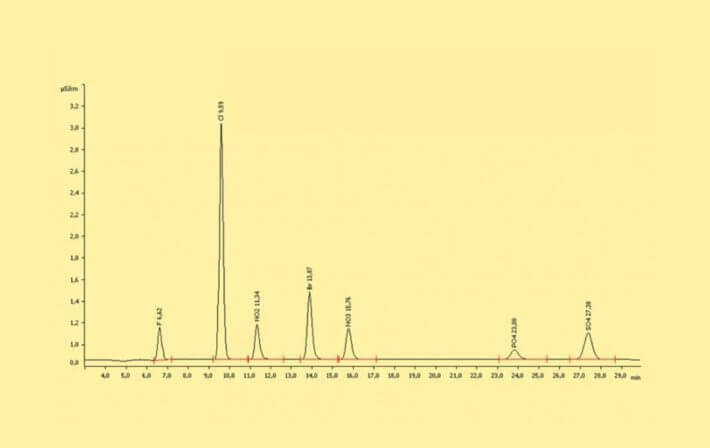

Measurement of extractable ionic contamination

Laboratory also performs cleanliness tests based on checking the presence of ionic contaminants on the analysed surfaces. Various types of samples can be tested, including printed circuit boards, enabling the determination of contaminants (e.g. soldering residues, residues from galvanic processes) that may lead to surface corrosion, affect the functionality of components or significantly impede further production processes.

Examples of research may include:

- preliminary assessment of the overall cleanliness assessment of printed circuit boards surfaces, assemblies of printed circuit boards or their components, based on measurement of the electrolytic conductivity of the solvent extract obtained from washing the tested surface. The test is carried out in accordance with IPC-TM-650 No. 2.3.25 – manual extraction method. The result of the test is the degree of surface contamination expressed as equivalent of dissolved salt in µg NaCl/surface area tested.

- detailed evaluation of the ionic purity of the surface under test. In the test a set of two ion chromatographs and appropriate standard solutions are used. Based on this, qualitative and quantitative analysis is possible, as well as determination of the main anions (including chlorides and bromides) as well as the main cations (sodium, ammonium, potassium). The methodology implemented enables determination of ions at low concentration levels (on the order of 1 mg/L). Additionally, determination of anions (fluoride, chloride, nitrite, nitrate, bromide, phosphate and sulphate) is possible. Among the cations, it is also possible to determine lithium, calcium and magnesium. The test is carried out for aqueous solutions, solutions from surface washing or solvent extraction performed at room or elevated temperature, e.g. in closed containers or bags with an appropriate cleanliness level (e.g. according to the IPC-TM-650 method No. 2.3.28.2).

- DIN 8964-1 – Circuit components for refrigerating systems – Part 1: Testing

- IPC-TM-650, Test Method 2.3.25 – Detection and Measurement of Ionizable Surface Contaminants by Resistivity of Solvent Extract (ROSE)

- IPC-TM-650, Test Method 2.3.28 – Test Method 2.3.28 Ionic Analysis of Circuit Boards by Ion Chromatography

- ISO 10304-1 – Jakość wody – Oznaczanie rozpuszczonych anionów za pomocą chromatografii jonowej – Część 1: Oznaczanie bromków, chlorków, fluorków, azotanów, azotynów, fosforanów i siarczanów

- ISO 14911 – Jakość wody – Oznaczanie Li+, Na+, NH4+, K+, Mn2+, Ca2+, Mg2+, Sr2+ i Ba2+ za pomocą chromatografii jonowej – Metoda dla wód i ścieków

- ISO 16232 – Road vehicles – Cleanliness of components and systems

- VDA 19.1 – VDA Volume 19 Part 1, Inspection of Technical Cleanliness – Particulate Contamination of Functionally Relevant Automotive Components

Powrót

do góry strony